Concrete Testing Near Me: Where Accuracy Satisfies Integrity in Task Guarantee

Concrete Testing Near Me: Where Accuracy Satisfies Integrity in Task Guarantee

Blog Article

Past the Surface area: Innovations in Concrete Testing Methods

Making certain the high quality and reliability of concrete frameworks needs complete testing and evaluation. From advanced imaging innovations and non-destructive screening methods to sophisticated sensors and monitoring systems, the area of concrete testing has actually observed exceptional progress. In this discussion, we will certainly check out these sophisticated developments that are shaping the future of concrete screening, revealing the interesting opportunities they provide for improving building and construction methods and making certain the longevity of our developed setting.

Advanced Imaging Technologies

One more innovative imaging modern technology used in concrete testing is ground-penetrating radar (GPR) GPR uses electromagnetic waves to find and map subsurface attributes, such as rebar, gaps, and delaminations. By providing real-time data on the condition of the concrete, GPR helps in identifying possible weak points or problems that may endanger its architectural honesty.

Moreover, progressed imaging modern technologies have actually reinvented the area of concrete petrography. Microscopic lens equipped with digital imaging capabilities enable detailed analysis of concrete examples at the microstructural degree. This makes it possible for the recognition of numerous components, such as concrete paste, aggregates, and extra products, along with the discovery of unhealthy reactions or wear and tear mechanisms.

Non-Destructive Testing Methods

Building upon the advancements in imaging modern technologies, the following area of focus in concrete screening includes the use of non-destructive testing methods. These approaches supply useful insights right into the architectural stability and performance of concrete without causing any kind of damages to the material. One generally utilized non-destructive testing method is the ultrasonic pulse rate (UPV) test. This technique entails sending high-frequency acoustic waves via the concrete and determining the time considered them to travel via the product. By analyzing the speed of these waves, engineers can establish the existence of any kind of flaws, such as spaces or cracks, within the concrete.

Another non-destructive testing technique is the impact-echo examination. This technique entails striking the surface of the concrete with a hammer and examining the resulting acoustical feedback. The impact-echo test is specifically helpful for identifying delamination, which is the separation of layers within the concrete. Furthermore, ground-penetrating radar (GPR) is a non-destructive screening method that utilizes electro-magnetic waves to produce photos of the subsurface of concrete frameworks. This technique can find the visibility of reinforcing bars, spaces, and other abnormalities within the concrete.

Non-destructive screening techniques supply numerous advantages over damaging testing techniques. They permit the analysis of bigger locations and give real-time outcomes. Moreover, they are affordable and decrease disturbances to recurring construction projects. By integrating non-destructive screening techniques into concrete testing methods, designers can get accurate and reliable information about the problem of concrete frameworks, guaranteeing their long-lasting toughness and safety and security.

High-Tech Sensors and Keeping Track Of Equipments

In the realm of concrete screening, the combination of high-tech sensing units and monitoring systems has actually changed the method designers gather information and examine the performance of frameworks. These sophisticated modern technologies supply real-time information on numerous parameters, such as temperature level, moisture web content, stress, and lots distribution, enabling a much more exact and extensive understanding of concrete actions.

One of the most substantial developments in this area is using embedded sensing units. These sensing units are embedded within the concrete during the building process and can constantly check the structural health and wellness of the concrete. They can identify early indications of wear and tear, such as splits or corrosion, and offer useful information for repair and maintenance decisions.

Another ingenious surveillance system is using cordless sensing units. These sensors can be put on the surface of the concrete or embedded within it, and they transfer information wirelessly to a main surveillance terminal. This removes the demand for manual data collection and permits real-time tracking of several specifications all at once.

In addition, the combination of sophisticated sensing units and monitoring systems has enabled the growth of anticipating versions for concrete performance. By gathering and examining information gradually, engineers can determine trends and patterns, enabling them to forecast future actions and make notified choices concerning repair and maintenance strategies.

Robot and Automation Solutions

The assimilation of sophisticated sensors and keeping an eye on systems in concrete screening has actually led the means for the execution of robot and automation remedies to further boost effectiveness and precision in analyzing the efficiency of frameworks. Robot and automation options supply a series of advantages in concrete screening, consisting of boosted efficiency, enhanced safety and security, and improved data collection.

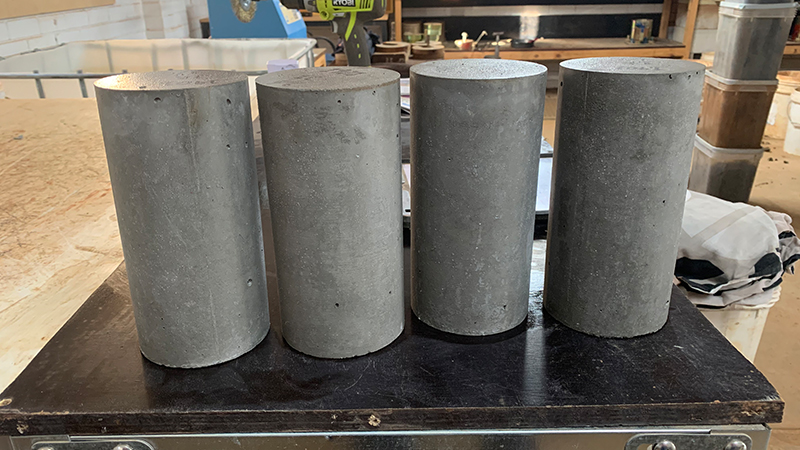

One area where robot options have been effectively applied is in the screening of concrete stamina - concrete testing near me. Traditional approaches include by hand gathering concrete samples and subjecting them to research laboratory testing.

Automation solutions likewise from this source play an important that site role in non-destructive screening techniques. For instance, autonomous drones outfitted with sensors can be made use of to examine huge concrete structures, such as dams or bridges. These drones can accumulate data on the structural honesty of the concrete, finding any indications of damages or wear and tear without the demand for manual assessment.

Artificial Knowledge in Concrete Testing

Expert system has transformed the area of concrete screening, offering sophisticated formulas and maker discovering capacities that improve the accuracy and effectiveness of analyzing the quality and performance of concrete frameworks. concrete testing near me. By taking advantage of the power of AI, scientists and engineers are able to examine substantial amounts of data to get beneficial insights into the behavior and toughness of concrete

One location where AI has actually made substantial developments is in non-destructive testing (NDT) Standard techniques of NDT need hand-operated analysis of information, which can be time-consuming and subjective. AI formulas, on the other hand, can examine data from different sources, such as sensing units and video cameras, in real-time and give immediate responses on the problem of the concrete. This not just conserves time however likewise enables for early detection of possible concerns, protecting against pricey fixings down the line.

Additionally, AI has also been used in predictive modeling to approximate the lasting performance of concrete frameworks. By inputting information on the structure of the concrete, environmental aspects, and loading conditions, AI formulas can forecast the architectural integrity and life-span of the concrete. This info is indispensable for engineers when creating new frameworks or examining the security of existing ones.

Final Thought

To conclude, innovations in concrete screening techniques have actually dramatically enhanced with the appearance of innovative imaging innovations, non-destructive testing approaches, state-of-the-art sensors and monitoring systems, robot and automation services, and expert system. These developments have enabled for more efficient and precise testing, causing much better quality assurance and longevity of concrete structures. Proceeded research study and growth in this field will certainly continue to boost the understanding and assessment of concrete homes, ensuring the durability and safety and security of construction jobs.

From advanced imaging modern technologies and non-destructive testing techniques to sophisticated sensors and keeping an eye on systems, the area of concrete testing has observed amazing development. By including non-destructive testing techniques right into concrete concrete testing near me screening protocols, engineers can get accurate and reliable information regarding the problem of concrete frameworks, ensuring their long-term longevity and safety.

These sensing units are embedded within the concrete during the construction procedure and can continuously monitor the structural health and wellness of the concrete. By inputting data on the make-up of the concrete, environmental variables, and loading problems, AI formulas can predict the architectural integrity and life-span of the concrete.In conclusion, advancements in concrete screening techniques have actually dramatically boosted with the emergence of advanced imaging modern technologies, non-destructive screening approaches, sophisticated sensors and checking systems, robotic and automation solutions, and fabricated intelligence.

Report this page